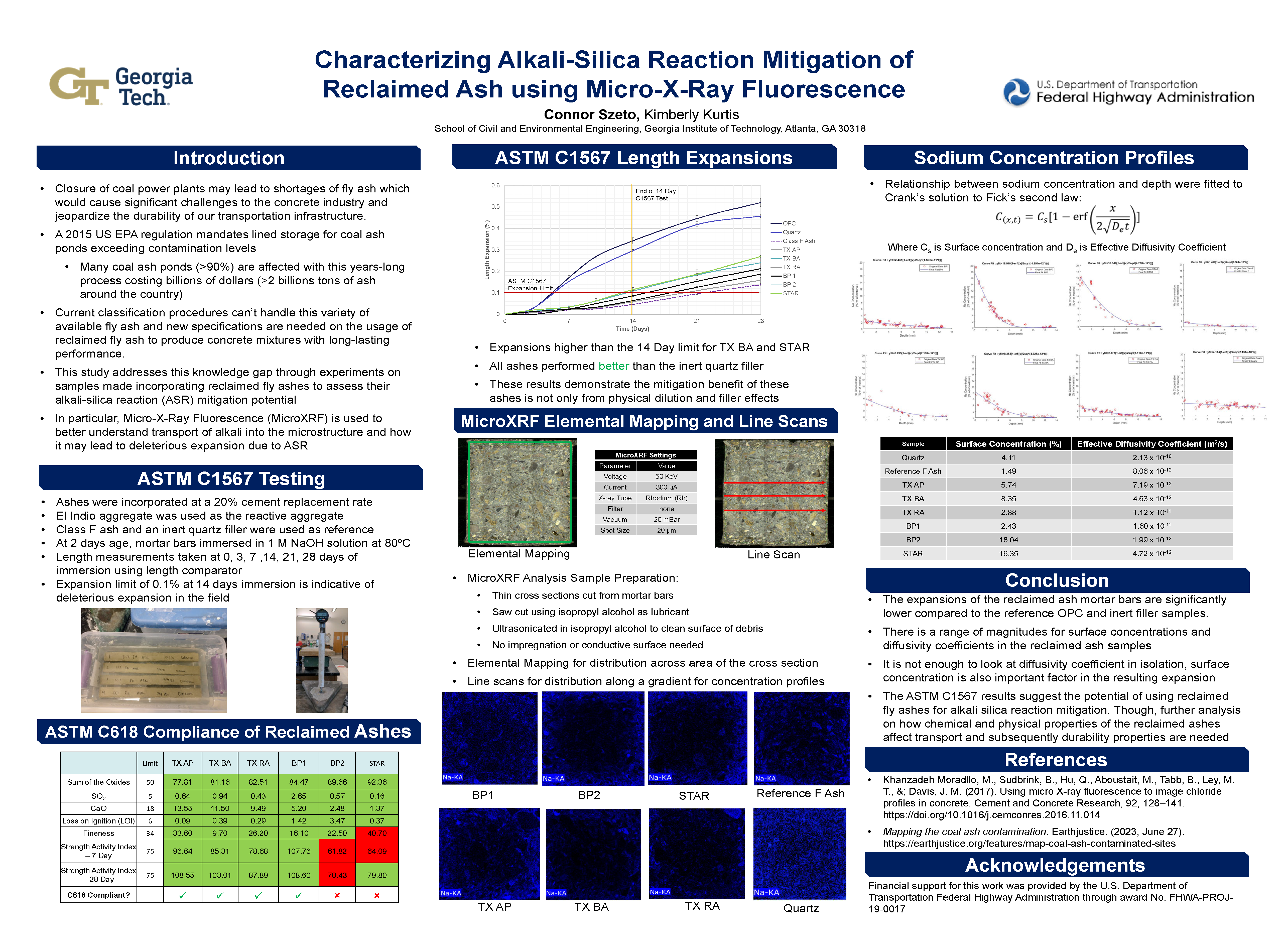

CHARACTERIZING ALKALI-SILICA REACTION MITIGATION OF RECLAIMED ASH USING MICRO-X-RAY FLUORESCENCE

PI: Kimberly Kurtis

Co-PI(s):

Institution(s): Georgia Institute of Technology

Abstract

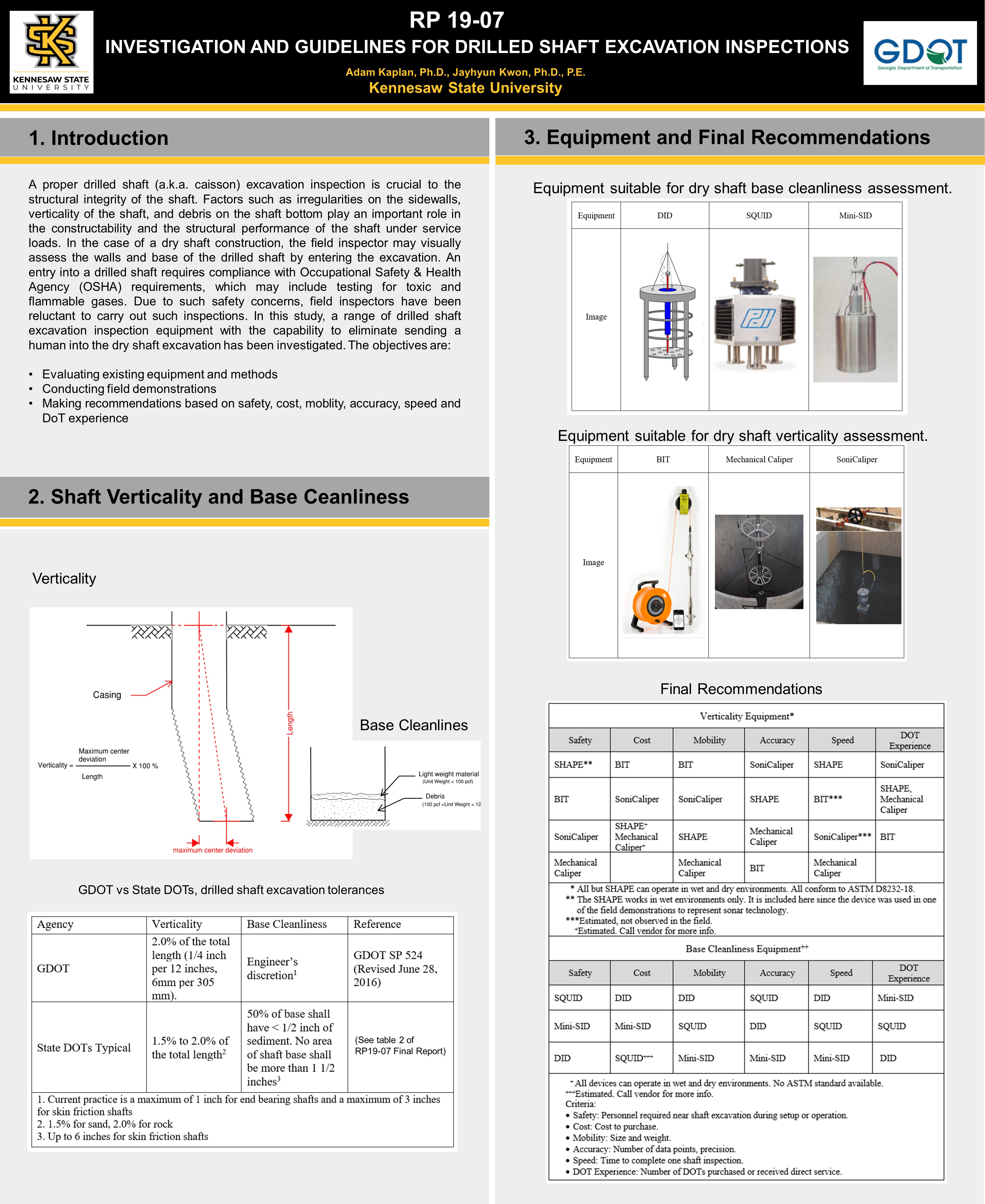

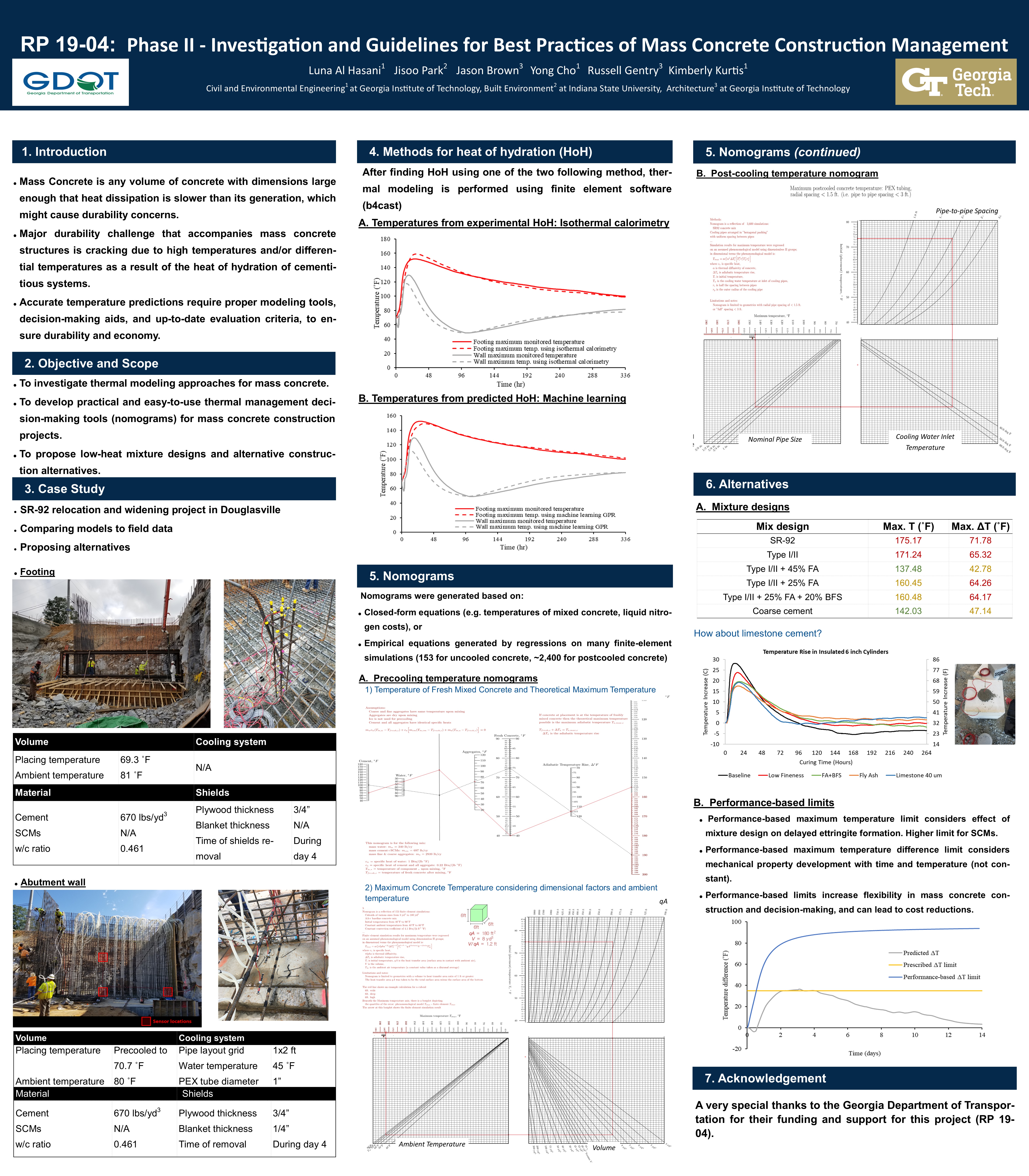

Over the past 80 years, concrete mixtures have become reliant on the use of fly ash to improve performance. The closure of coal power plants in the US has raised concerns about the supply of traditional fly ash. Fortunately, there are billions of tons of fly ash stored in solid waste disposal sites that can be easily accessed. However, current classification procedures are not suited to handle this variety of available ash and new specifications are needed on the usage of reclaimed fly ash to produce concrete mixtures with long-lasting performance. This study addresses this knowledge gap through experiments on samples made incorporating reclaimed fly ashes. Mortar bar samples were subjected to an aggressive and accelerated test to assess the alkali-silica reaction (ASR) mitigation potential of the reclaimed ashes. At the end of the test duration, Micro-X-Ray Fluorescence (MicroXRF) analysis was conducted to better understand transport of alkali into the microstructure and how it may lead to deleterious expansion due to ASR. The results showed that the length expansions of the reclaimed ash mortar bars were significantly lower compared to the reference OPC and inert filler samples. From the MicroXRF analysis, there was a range of magnitudes for surface concentrations and diffusivity coefficients in the reclaimed ash samples. This showed that it is not enough to look at diffusivity coefficient in isolation as surface concentration is also important factor in the resulting expansion. Overall, the results of this study suggest the potential of using reclaimed fly ashes for alkali silica reaction mitigation in concrete.

Please comment below with any statements or questions you may have. Also let GTI if you would be interested webinars or presentations on similar topics.