PHASE II – INVESTIGATION AND GUIDELINES FOR BEST PRACTICES OF MASS CONCRETE CONSTRUCTION MANAGEMENT

PI: Yong Cho

Co-PI(s): Kimberly Kurtis, and Russell Gentry

Institution(s): Georgia Institute of Technology

Abstract

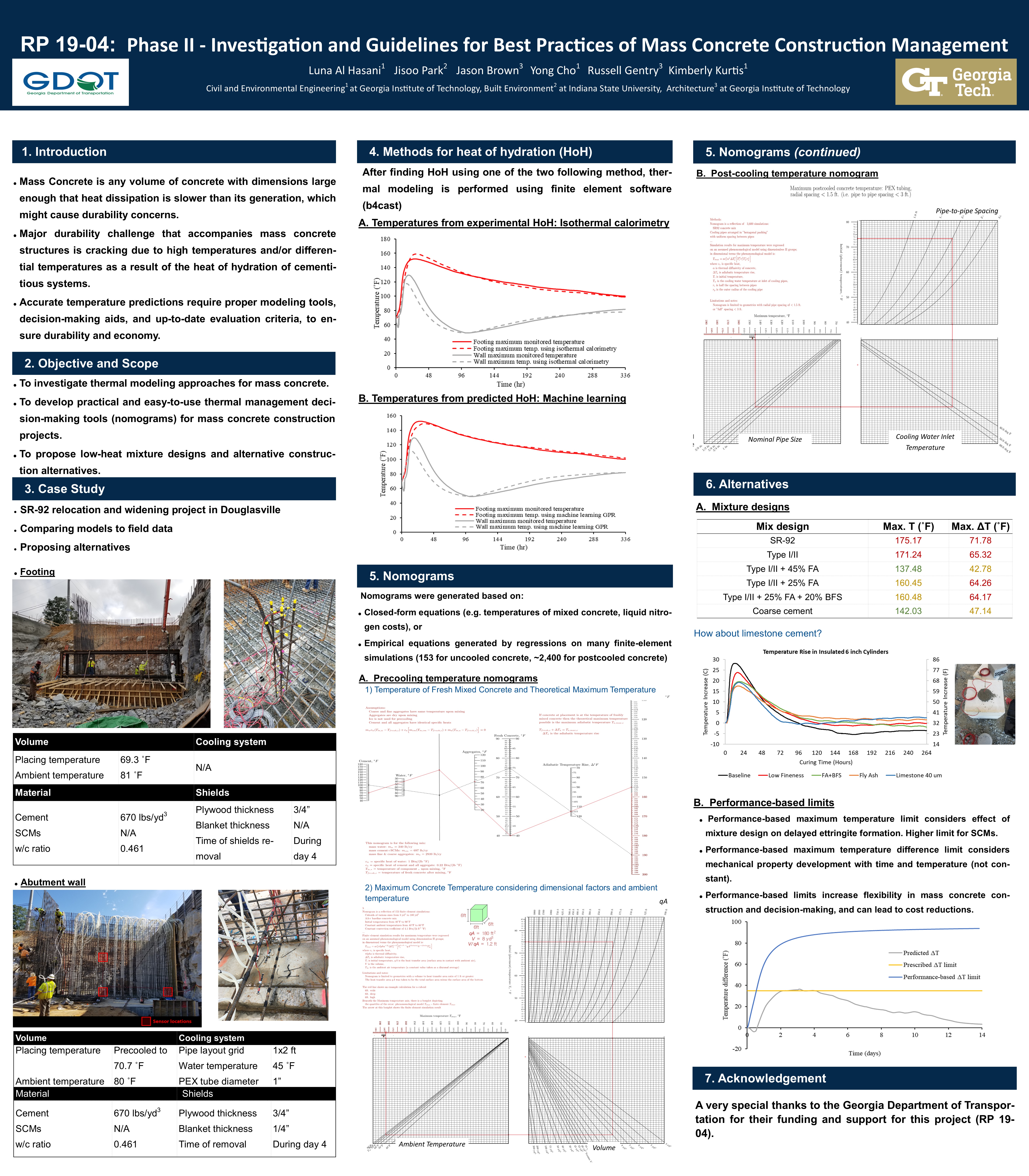

The durability of mass concrete structures may be compromised due to stresses and cracking induced by temperature rise due to hydration of the concrete, and subsequent cooling. Delayed ettringite formation and thermal cracking may occur when maximum temperatures and maximum temperature differentials, respectively, are greater than the allowable thresholds. Construction practices in mass concrete scenarios, therefore, seek to limit maximum and differential temperatures below acceptable limits. This work investigates a mass concrete abutment wall that was constructed as part of relocating and widening a state road in Douglasville, Georgia beneath a railway line. Thermal control measures for the construction of the wall included both precooling of the concrete at the ready-mix plant using liquid nitrogen and post-cooling the abutment wall using internal cooling pipes. Both of these technologies increased the cost and complexity of construction. This research focuses on developing means to better characterize the heat of hydration of the cements and SCMs and temperature rise of concretes proposed for the project, and on proposing means to construct the abutment wall with less stringent and less costly thermal control measures. Alternative modeling approaches using isothermal calorimetry and machine learning, as well as nomogram decision-making tools have been proposed. Further analysis has been completed to investigate alternative design and construction options to satisfy maximum and differential temperature limits imposed by Georgia DOT guidelines. The variables considered are types and finenesses of cementitious materials, mix designs, concrete placement temperatures, and time of removal of insulation and formwork. It has been found that the accuracy of the thermal modeling can be improved with up-to-date techniques. The research concludes that both maximum and differential thermal limits could have been satisfied and post-cooling eliminated with the use of alternative materials and performance-based limits. The investigation shows that with proper heat of hydration modeling and decision-making tools, the cost and complexity of mass concrete construction can be significantly reduced.

Please comment below with any statements or questions you may have. Also let GTI if you would be interested webinars or presentations on similar topics.