INVESTIGATION AND GUIDELINES FOR DRILLED SHAFT EXCAVATION INSPECTIONS

PI: Adam Kaplan

Co-PI(s): Jayhyun Kwon

Institution(s): Kennesaw State University

Abstract

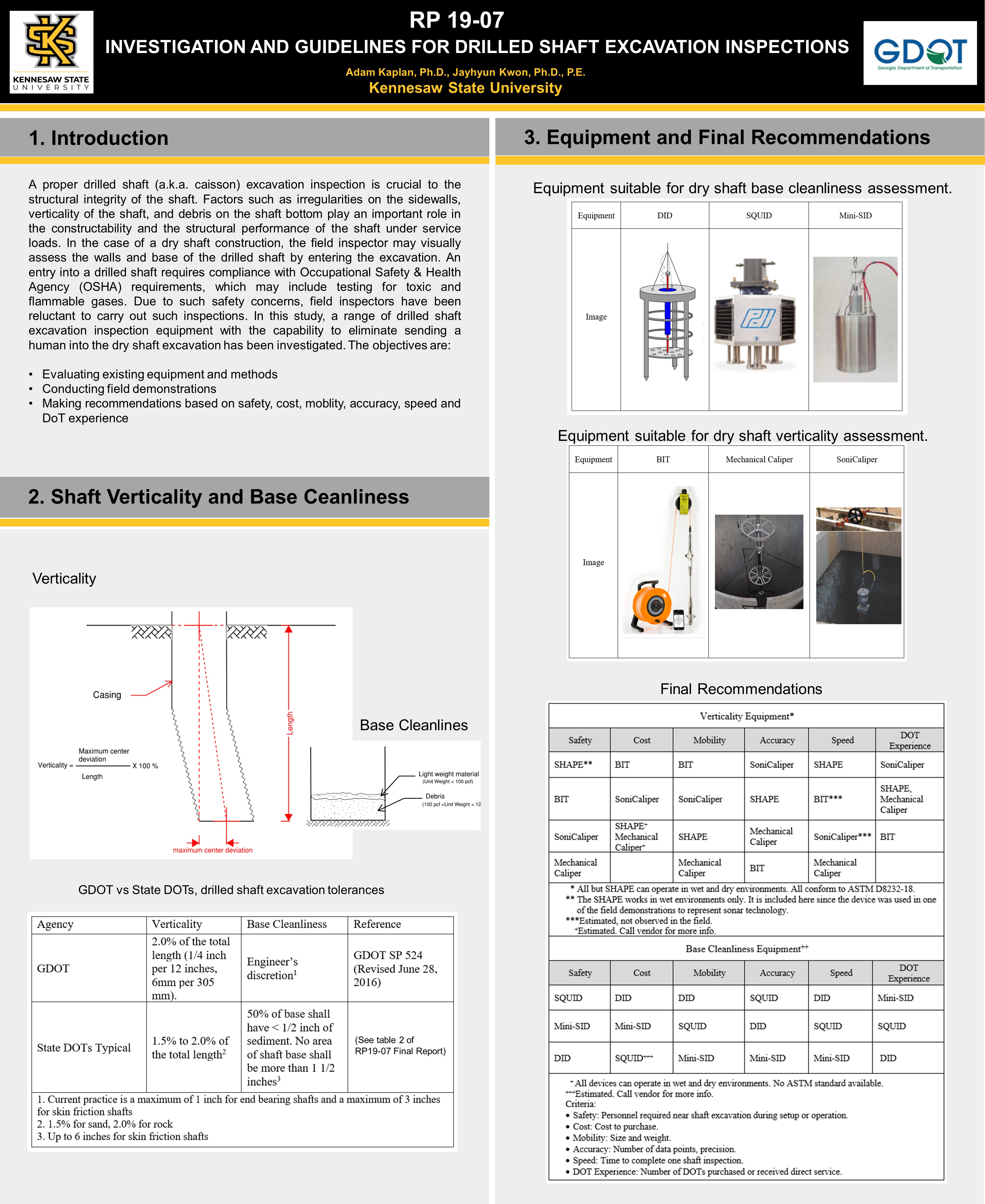

A proper drilled shaft (a.k.a. caisson) excavation inspection is crucial to the structural integrity of the shaft. Factors such as irregularities on the sidewalls, verticality of the shaft, and debris on the shaft bottom play an important role in the constructability and the structural performance of the shaft under service loads. In the case of a dry shaft construction, the field inspector may visually assess the walls and base of the drilled shaft by entering the excavation. An entry into a drilled shaft requires compliance with Occupational Safety & Health Agency (OSHA) requirements, which may include testing for toxic and flammable gases. Due to such safety concerns, field inspectors have been reluctant to carry out such inspections. In this study, a range of drilled shaft excavation inspection equipment with the capability to eliminate sending a human into the dry shaft excavation has been investigated. The objectives are: 1) Evaluating existing equipment and methods 2) Conducting field demonstrations 3) Making recommendations based on safety, cost, moblity, accuracy, speed and DoT experience

Please comment below with any statements or questions you may have. Also let GTI if you would be interested webinars or presentations on similar topics.