Poster 22-21

Phase III - Investigation and Guidelines for Best Practices of Mass Concrete Construction Management

PI: Yong K. Cho

Co-PI(s): Kimberly Kurtis, and Russell Gentry

Institution(s): Georgia Institute of Technology

Abstract

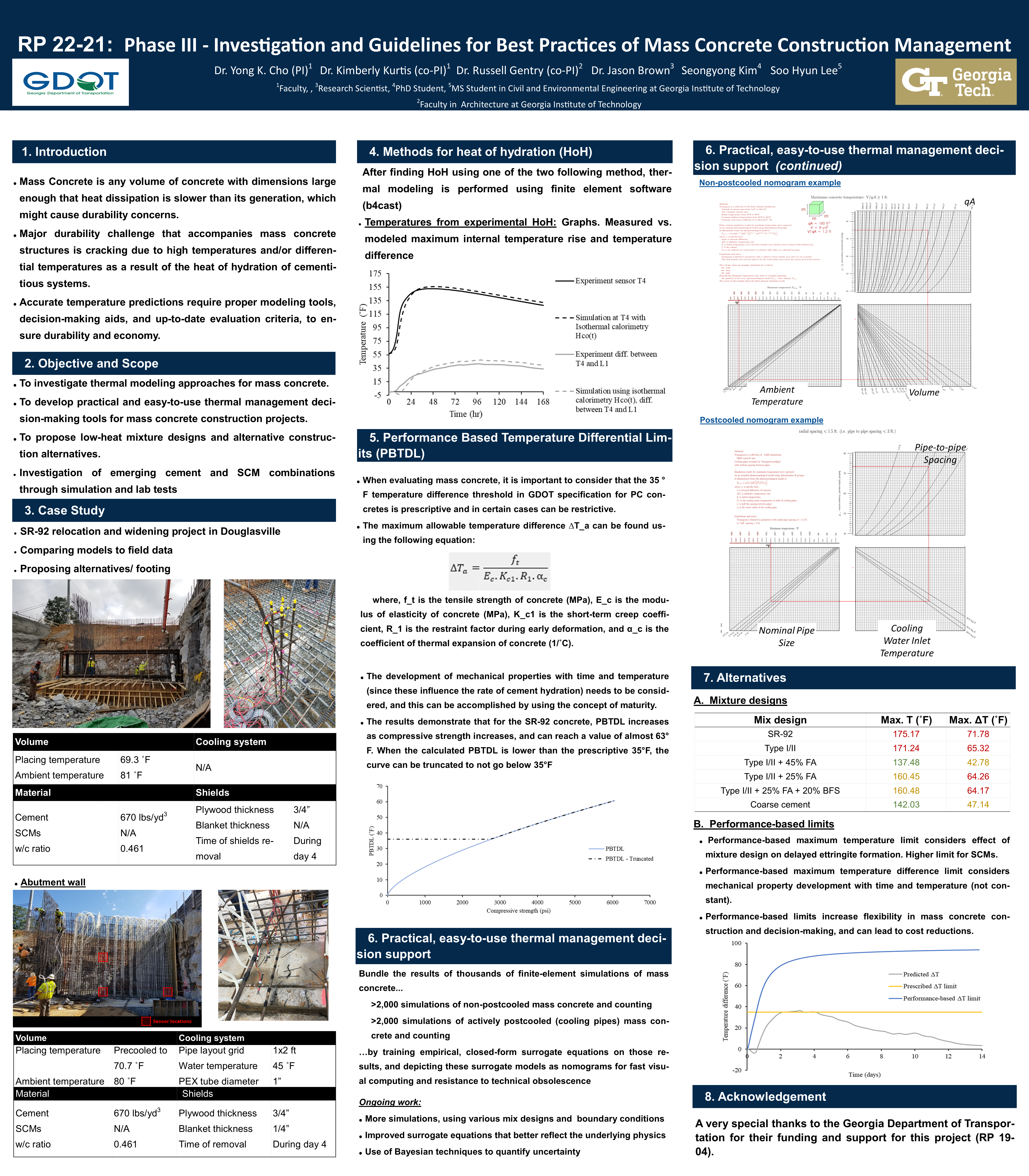

The Georgia Department of Transportation (GDOT) defines mass concrete as "any large volume of cast-in-place concrete with dimensions large enough to require that measures be taken to cope with the generation of heat and attendant volume change to minimize cracking?. If mass concrete overheats due to the exotherm, the concrete may self-destruct due to delayed ettringite formation (DEF) in the worst case or may experience early-age cracking due to thermal differentials, which is not a fatal problem, but such cracking could lead to long-term durability problems. Thus, a false choice of temperature reduction methods utilized by contractors would decrease the quality of the concrete or structure, which could be costly for GDOT to maintain the possibly resulting defects. This research aims to expand the applicability of decision-making tools to various concrete mixes, including accommodating temperature differential and cost implications while exploring emerging cement and SCM combinations. The research team will also identify a time-cost tradeoff among different thermal control methods to increase the net benefit of a mass concrete construction project. The specific scope of the work to be completed within this research project includes, 1) investigation of emerging cement and SCM combinations through simulation and lab tests, 2) validation, extension, and refinement of the nomograms developed from Phase II, 3) identification of time-cost tradeoff among thermal control methods, and 4) investigation of� alternative methods to avoid active cooling.

Please comment below with any statements or questions you may have. Also let GTI if you would be interested webinars or presentations on similar topics.

Theme by Danetsoft and Danang Probo Sayekti inspired by Maksimer